AI News & Trends

AI-driven Industrial Efficiency, Artificial Intelligence in Industrial Automation, Automation Technology Trends, Data Analytics for Industrial Optimization, Industry 4.0 Innovations, Intelligent Automation Systems, Machine Learning Applications in Industry, Robotics and Automation Technologies, Smart Manufacturing Solutions

admin trends ai

0 Comments

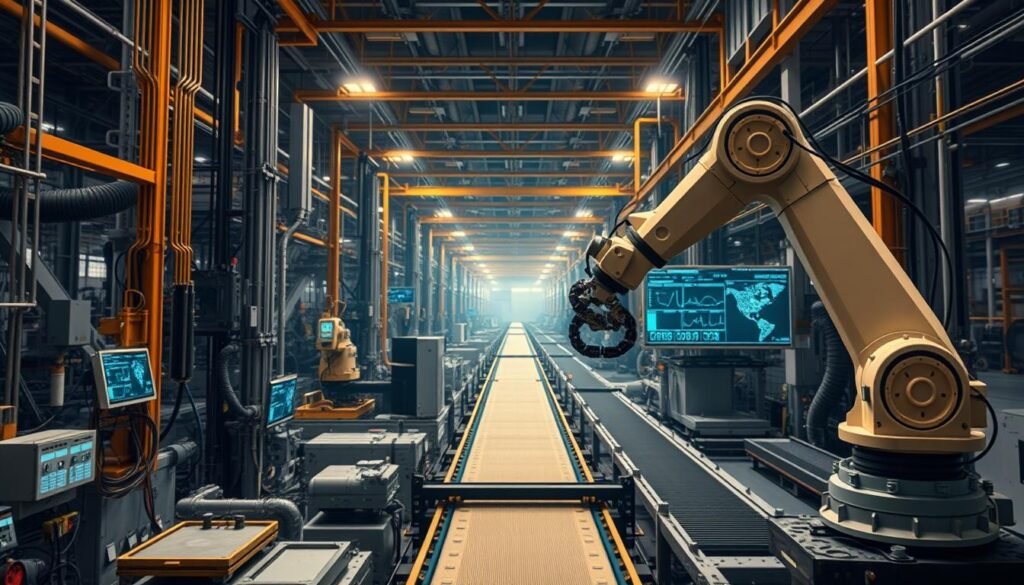

Unlocking the power of AI in industrial automation

Can artificial intelligence really change the game in manufacturing? As we’re on the edge of a new tech era, this question is more pressing than ever.

A 2024 Innova survey shows AI adoption in manufacturing is taking off. It’s expected to reach almost complete adoption in just two years. This rise highlights the key role of AI in industrial automation, changing how we make things.

Adding AI to the mix is more than a trend; it’s a major shift. It boosts efficiency, cuts costs, and makes products better.

Key Takeaways

- Rapid adoption of AI in manufacturing is projected to continue.

- AI enhances efficiency and reduces production costs.

- Improved product quality through AI-driven automation.

- Significant potential for innovation in manufacturing processes.

- Future of manufacturing heavily reliant on AI technologies.

The Rising Tide of AI in Industrial Automation

In recent years, AI has become more popular in factories, changing how things are made. This change is because companies want to work better, faster, and more efficiently. They need to keep up with the fast-changing world market.

Latest Breakthroughs Reshaping Factory Floors

AI has made big changes in how factories work. Machine learning algorithms help make production better, predict when things need fixing, and improve product quality. For example, AI can spot problems with products right away, cutting down on waste and making things more efficient.

Some major advancements include:

- Advanced predictive maintenance capabilities

- Enhanced quality control through AI-powered inspection systems

- Improved production planning and scheduling

Record Investment Levels in Q1 2023

In the first quarter of 2023, there was a huge amount of money put into AI for factory automation. Reports show that investments in AI technologies for automation hit new highs. This is because companies need to stay ahead and adjust to new market demands.

| Investment Area | Q1 2023 Investment | Growth vs. Q1 2022 |

|---|---|---|

| AI in Factory Automation | $1.2 Billion | +25% |

| Industrial Robotics | $800 Million | +30% |

| Machine Learning Solutions | $500 Million | +40% |

The U.S. Departments of Labor, Commerce, and Education’s “America’s Talent Strategy” report shows the government’s focus on leading in AI. This highlights the big potential for AI growth in different industries.

Major Industry Players Advancing Manufacturing AI Solutions

The manufacturing world is changing fast, thanks to AI from big players. We’re seeing smart factories and more use of the industrial internet of things (IIoT). These are getting better with AI in industrial control systems.

Tech Giants’ Recent Industrial Automation Initiatives

Big tech companies are leading in AI for making things. For example, Fujitsu teamed up with NVIDIA to make AI infrastructure. This partnership aims to make manufacturing better by using AI for real-time improvements and finding problems early.

Some big moves from tech giants include:

- Creating AI for fixing machines before they break, cutting down on lost time.

- Using AI to check product quality and lower mistakes.

- Building AI tools for better supply chain and inventory management.

Emerging Startups Disrupting Traditional Automation

New startups are also key in AI for making things. They’re quick to try new ideas and shake up old ways of doing things.

Some cool things from new startups are:

- Coming up with special AI for industrial control systems, making making things more precise and fast.

- Building AI robots that can adjust to new needs in production.

- Starting AI data analytics for quick insights into how things are made.

Together, big tech and new startups are making big steps in AI for making things. This means better efficiency, more production, and staying ahead in the game.

Machine Learning for Industrial Processes: New Implementations

New uses of machine learning are changing how we make things. It helps make production better and safer. It also makes making new products faster. This change is making factories work better and faster.

Real-Time Production Optimization Systems

Systems that optimize production in real-time are now common. They use machine learning algorithms to look at data and predict problems. This helps factories work more efficiently and save money.

The good things about these systems include:

- More things made

- Less energy used

- Better quality products

Anomaly Detection Algorithms Preventing Manufacturing Defects

Algorithms that find problems before they start are being used. They look at past data and current activity to spot issues. This helps avoid bad products and saves money.

Here’s how machine learning compares to old ways of checking quality:

| Method | Defect Detection Rate | Response Time |

|---|---|---|

| Traditional Quality Control | 80% | Several Hours |

| Machine Learning Enhanced | 95% | Real-Time |

Using machine learning for industrial processes makes factories better. It helps them work more smoothly and less often stop. As machine learning gets better, we’ll see even more cool uses in factories.

Industrial Robotics and AI: The Evolving Partnership

AI is becoming key in the growth of industrial robotics. This partnership is changing factory automation. It makes things more efficient, precise, and adaptable.

The team-up of industrial robotics and AI is more than a trend. It’s a big change in how we make things. Companies like Fujitsu and NVIDIA are leading this change. They’re using AI agents that keep getting better.

Next-Generation Collaborative Robots Entering Production

New collaborative robots, or cobots, are being made. They work with humans to make things better and safer. These cobots use advanced AI to learn and adapt to new tasks.

- Improved safety features through advanced sensor systems

- Enhanced flexibility in task execution

- Increased productivity through seamless human-robot collaboration

Key Features of Next-Generation Cobots:

- Advanced AI for real-time decision-making

- Enhanced sensor capabilities for improved safety

- Flexibility in programming for diverse tasks

AI-Driven Adaptability in Robotic Systems

AI is making robots more adaptable. They can now change to meet new production needs quickly. This is important in today’s fast world of making things.

The Future of Industrial Robotics:

“The future of industrial robotics lies in the seamless integration of AI, enabling robots to not only perform tasks but to learn, adapt, and improve over time.”

The partnership between industrial robotics and AI is growing. We’ll see more new uses in factory automation soon. This could lead to big gains in efficiency, productivity, and safety. Companies that use this tech will likely lead their markets.

Smart Factories Technology: The AI-IoT Convergence

The fusion of artificial intelligence and the Internet of Things is changing smart factories. This new era brings innovation and efficiency to the forefront.

Industrial environments are getting more connected. AI and IoT devices are working together for better data analysis and decision-making. This teamwork boosts efficiency and makes manufacturing systems more adaptable and responsive.

Industrial Internet of Things (IIoT) Integration Milestones

The Industrial Internet of Things (IIoT) is key in smart factories. It connects machines, sensors, and devices for real-time monitoring and control. Recent IIoT milestones include advanced sensor networks and better data analytics platforms.

These steps help manufacturers understand their operations better. They can optimize production and improve product quality. For example, IIoT’s predictive maintenance cuts downtime and boosts equipment effectiveness.

Digital Twin Implementations Across Manufacturing Sectors

Digital twin technology is another important part of smart factories. It creates virtual copies of physical assets. This lets manufacturers test and optimize equipment and production lines virtually.

Digital twins are being used in many sectors, from cars to aerospace. They help improve product design, production planning, and efficiency. The Manufacturing Skill Standards Council (MSSC) has also added AI and Industry 4.0 technologies to its Certified Production Technician (CPT) program.

As smart factories grow, AI and IoT will be crucial. They will help companies reach new heights of efficiency, productivity, and innovation.

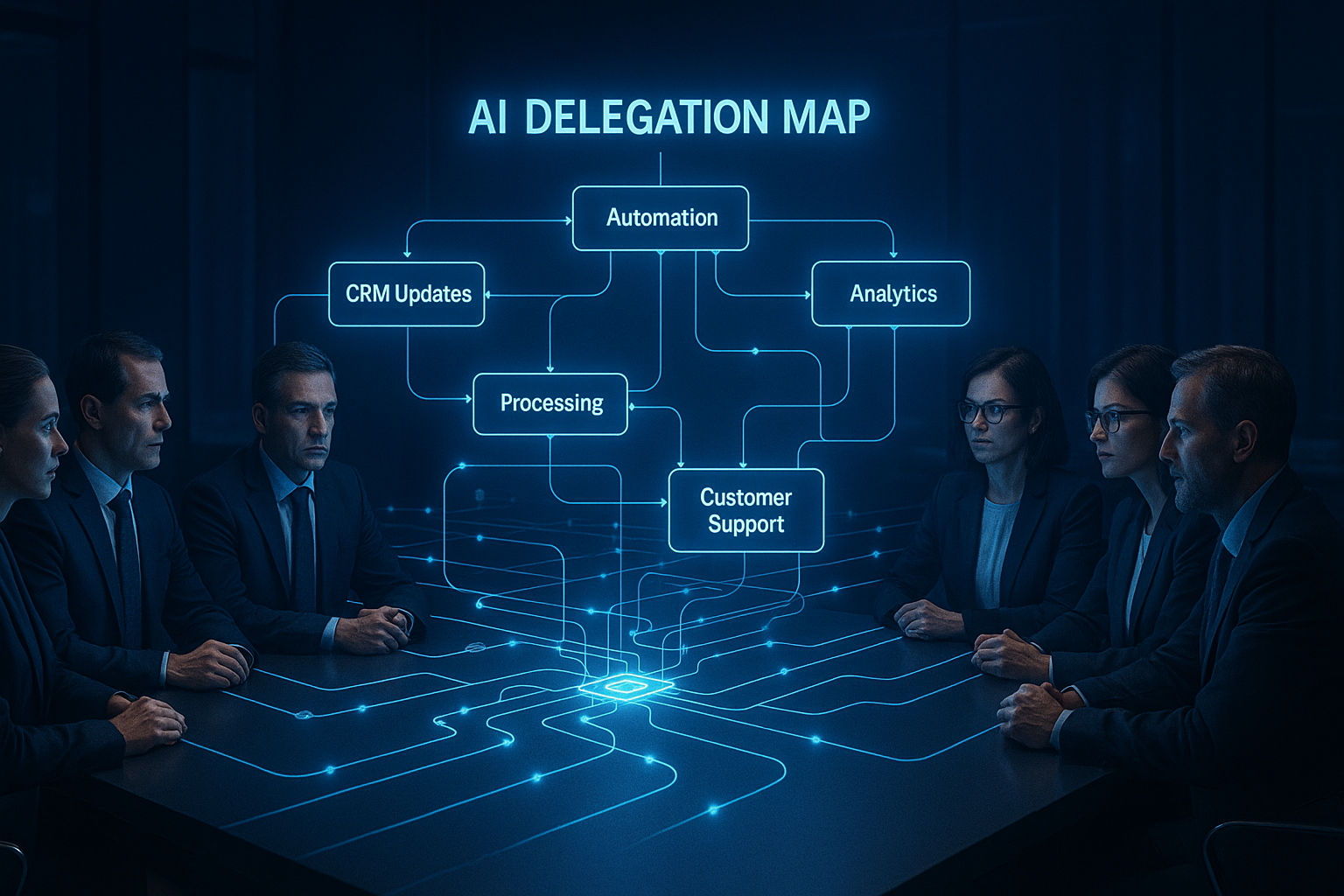

Breaking News: AI Applications in Industrial Control Systems

AI is changing industrial control systems with smart decision-making and flexible control. New advancements are making industries work better and faster. They also help respond quickly to new situations.

Autonomous Decision-Making Frameworks Launched This Quarter

The Manufacturing Skills Standards Council (MSSC) has started an AI Study Group. They aim to find out what AI skills are needed for manufacturing workers. This shows how important AI is becoming in factories.

These smart frameworks have cool features:

- They process data fast for quick decisions

- They use predictive analytics to spot problems ahead

- They adjust themselves to make processes better

Adaptive Control Systems Responding to Market Volatility

Adaptive control systems are becoming more common to handle market changes. They use AI to tweak production settings on the fly. This keeps manufacturing running smoothly, even when the market shifts.

The good things about these systems are:

- They make production plans more flexible

- They help factories deal with supply chain problems

- They keep production in line with what customers want

By using AI in control systems, companies can stay ahead in a fast-changing market.

Predictive Maintenance in Manufacturing: New AI Models

Manufacturers are now using AI for predictive maintenance to boost efficiency. They can predict when equipment will fail, cutting downtime and boosting productivity.

Advanced Sensor Networks Detecting Pre-Failure Conditions

Advanced sensor networks are key to predictive maintenance. They watch equipment all the time. Sensors spot small problems early, helping teams act fast.

Vibration sensors find issues in moving parts, and temperature sensors catch overheating. AI then analyzes this data to forecast failures. This way, teams can fix problems before they get worse, cutting down on unexpected stops.

Cost-Benefit Analysis of Recent Implementations

AI predictive maintenance has saved a lot of money for companies. It cuts down on unplanned stops and makes equipment last longer. For example, a big car maker saw a 30% drop in maintenance costs after using these tools.

- Less money spent on maintenance thanks to smart fixes

- More time running and more work done

- Safe work places by spotting dangers early

As AI gets better, we’ll see even more advanced tools for predictive maintenance. This will help manufacturers even more.

Computer Vision Revolutionizing Quality Assurance Processes

Computer vision is changing how we check products in factories. It makes checking products faster and more accurate.

It helps make products quicker and lets designers try new things. This is thanks to fast inspection systems and new ways to find defects.

High-Speed Inspection Systems Deployed in 2023

In 2023, big companies started using fast inspection systems. These use computer vision to spot problems on the production line. This makes checking products much quicker.

The good things about these systems are:

- They find defects better

- They save money by not needing as many people

- They keep products better by checking them as they’re made

Multi-Modal Defect Detection Technologies

These new systems use different ways to check products. They look at visual, thermal, and ultrasonic data. This gives a full picture of product quality.

Here’s a table comparing different ways to find defects:

| Technology | Defect Detection Capability | Inspection Speed |

|---|---|---|

| Visual Inspection | Surface defects | High |

| Thermal Inspection | Internal defects | Medium |

| Ultrasonic Inspection | Deep internal defects | Low |

Using all these methods together makes quality checks better. It means fewer bad products make it to the market.

Automation Software Solutions: The Intelligence Layer

Industrial automation is growing, and software solutions play a big role. These solutions help factories work better, predict when they need maintenance, and keep up with market changes.

Cloud-Based vs. Edge-Based Processing Architectures

Choosing between cloud-based and edge-based processing is key. Cloud solutions are flexible and can handle big data. Edge processing is fast and good for making quick decisions.

Comparison of Cloud-Based and Edge-Based Architectures

| Feature | Cloud-Based | Edge-Based |

|---|---|---|

| Scalability | High | Limited |

| Latency | Higher | Lower |

| Real-Time Processing | No | Yes |

| Data Security | Dependent on Cloud Provider | More Control |

API Ecosystems Connecting Factory Systems

API ecosystems are key in linking factory systems. They make sure data flows smoothly between different systems. This way, manufacturers can use various software together, like ERP, MES, and SCADA.

Fujitsu and NVIDIA’s collaboration on AI infrastructure is a big step. It shows how integrating different technologies can boost automation software. This leads to better data analysis and smarter decisions.

API ecosystems and automation software are changing the industrial world. They help systems talk to each other, making factories more efficient. This leads to lower costs and better products.

Edge Computing Bringing AI Directly to Production Lines

Manufacturers can now use AI right where it’s needed thanks to edge computing. This tech mix is changing how we automate industries. It makes production faster, more efficient, and safer.

Edge computing puts AI on the production line. This cuts down on delays and boosts quick decision-making. In fast-paced settings, every microsecond counts.

Microsecond Response Times Enabling New Applications

Real-time data processing opens up new chances for automation. Edge computing lets AI systems respond fast to production changes. This makes things like:

- Predictive maintenance, where equipment gets fixed before it breaks

- Real-time quality control, catching and fixing defects right away

- Dynamic production scheduling, adjusting lines quickly

Experts say, “Edge computing and AI will change manufacturing. They’ll make production systems more agile and quick.”

Data Security Protocols for Sensitive Manufacturing Data

Edge computing brings big benefits but also new security risks. To keep data safe, strong security steps are being taken. These include:

- Encrypting data in transit and at rest

- Secure ways to log in for devices and users

- Regular checks to make sure everything is secure

By using edge computing with solid security, factories can run AI-driven lines efficiently and safely.

AI in manufacturing is on the rise. 95% of top companies worldwide are using or planning to use AI in the next five years. So, edge computing and data security will become even more key.

Industry Leaders Implementing AI in Industrial Automation

AI is changing how we make things in big ways. It’s making a big splash in the automotive and pharmaceutical industries. A survey by the Manufacturing Leadership Council found that 68% of makers think AI is key to staying ahead. This shows how important AI is for growth.

Automotive Sector Transformation Through AI

The car world is changing fast thanks to AI. It’s making cars better, cheaper, and faster to make. AI helps guess when parts need fixing, so cars don’t sit idle for long.

Some cool AI uses in cars include:

- Predictive maintenance

- Quality control through computer vision

- AI-driven robotics for assembly and inspection

Pharmaceutical Manufacturing AI Adoption

The drug-making world is also getting a boost from AI. It helps plan better, check quality, and follow rules. For example, AI looks at data to spot problems early.

| Sector | AI Application | Benefit |

|---|---|---|

| Automotive | Predictive maintenance | Reduced downtime |

| Pharmaceutical | Quality control | Improved product quality |

| Automotive | AI-driven robotics | Enhanced assembly efficiency |

As AI keeps changing how we make things, leaders in cars and drugs are set to gain a lot. By using AI, they can work smarter, spend less, and innovate more.

Challenges and Solutions in Industrial AI Adoption

As more companies adopt industrial AI, they face big challenges. These challenges include technology, operations, and people. It’s a complex journey.

“The biggest challenge is not the technology itself, but how to effectively integrate it into existing systems and processes,” says industry experts. This shows the need for strong strategies to overcome these hurdles.

Legacy System Integration Breakthroughs

One major challenge is making AI work with old systems. Many factories use systems from decades ago. These systems weren’t made for AI.

Modernization initiatives are starting to fix this. Companies are creating software that connects old systems with new AI apps.

An example is API-based integration. It lets data flow smoothly between old and new systems. This makes systems work better together.

Data Quality Management Frameworks

Data quality is key for industrial AI to work well. AI needs good, relevant data to give accurate insights.

Organizations are setting up data quality management frameworks. These include steps for cleaning, checking, and making data consistent. This ensures AI gets reliable data.

- Data validation checks

- Automated data cleansing processes

- Regular data audits

Workforce Upskilling Initiatives

AI in factories means workers need new skills. As AI does routine tasks, workers must learn to manage and keep these systems running.

The Manufacturing Skill Standards Council (MSSC) has found 18 key skills for AI in manufacturing. These include quality control and reducing errors. Companies are investing in training for these skills.

“The future of manufacturing is not just about technology; it’s about people who can harness that technology to drive innovation and efficiency.”

Upskilling includes both technical and soft skills. Workers need to know how to use AI tools well. They also need to work well with these systems.

Regulatory Landscape for AI-Powered Manufacturing

The use of AI in manufacturing has changed the rules. As AI becomes more common in factories, governments are working hard. They aim to make sure AI is safe, secure, and promotes innovation.

New Safety Standards for Autonomous Industrial Systems

AI has led to new safety rules for factories. These rules make sure AI machines work well with people. For example, Executive Order 14179 has helped set standards for AI in factories.

The President’s AI Action Plan, based on this order, gives clear guidelines. It talks about testing AI systems and adding safety features to avoid accidents.

| Safety Standard | Description | Implementation Timeline |

|---|---|---|

| AI System Testing | Rigorous testing of AI systems to ensure safe operation | Q2 2023 |

| Fail-Safe Mechanisms | Implementation of fail-safes to prevent accidents | Q3 2023 |

| Human-AI Collaboration | Guidelines for safe human-AI collaboration in manufacturing | Q4 2023 |

International Harmonization Efforts for AI in Critical Infrastructure

AI is key to critical infrastructure, so countries are working together. They aim to make sure AI systems meet global safety and security standards. This involves teamwork between governments, industry leaders, and regulatory bodies.

This effort is important to avoid different rules in different places. It helps AI-powered manufacturing solutions work worldwide. By having one set of rules, companies can follow them easily everywhere.

The rules for AI in manufacturing are getting better. As these rules change, companies need to keep up. This helps them follow the rules and stay ahead in the market.

Economic Impact: How AI is Reshaping Industrial Competitiveness

AI is changing the game in manufacturing. It makes operations more efficient and cuts costs. This boosts the competitiveness of industries.

When companies use AI, they see better visibility and speed. This lets them meet market needs quickly. It gives them an edge over others.

Reshoring Trends Enabled by Automation

AI is also making companies bring jobs back home. It automates tough tasks and makes products better. This makes it easier to manufacture locally.

This move is because of less need for manual work. Being close to the market helps with faster delivery and lower shipping costs.

Productivity Gains Across Manufacturing Sectors

AI is making manufacturing more productive. It optimizes processes, predicts when things need fixing, and checks product quality. This leads to more output with less waste and lower costs.

This makes the manufacturing sector more competitive. It can adapt to market changes quickly and efficiently.

Future Outlook: The Next Wave of Robotics in Factory Automation

The future of robotics in factory automation is exciting. New technologies will change how we work. Manufacturers want to be more efficient and flexible, and robotics will help a lot.

Artificial intelligence (AI) and machine learning (ML) are making robots smarter. These smart robots can adapt to different needs. This means factories can change quickly to meet new demands.

Emerging Technologies Set to Disrupt Industrial Processes

Several new technologies are changing how we work:

- Advanced Computer Vision: Better vision will help catch mistakes and improve quality.

- Collaborative Robots (Cobots): New cobots will work well with people, making work safer and more efficient.

- Autonomous Mobile Robots (AMRs): AMRs will change how we move things around in factories.

Industry Forecasts for 2024-2025

Experts think more factories will use robots and automation soon. Here are some trends to watch:

| Trend | Description | Expected Impact |

|---|---|---|

| Increased Adoption of AI-Powered Robots | More factories will use AI and ML in their robots. | Work will be more efficient and cheaper. |

| Growth in Collaborative Robotics | Cobots will be used more in different types of factories. | Work will be safer and more flexible. |

| Rise of Edge Computing in Robotics | Edge computing will help robots make decisions faster. | Factories will be more responsive and productive. |

As these new technologies grow, they will bring big changes to factories. Factories will work better, be more productive, and stay competitive.

Conclusion: The Transformative Journey of AI in Industrial Automation

AI is changing the game in manufacturing, marking a big step forward. It’s making operations more efficient, cutting costs, and improving product quality. The Manufacturing Skill Standards Council (MSSC) is adding AI and Industry 4.0 tech to its Certified Production Technician (CPT) program. This shows how crucial these technologies are becoming.

As AI gets better, it will bring more changes to industrial automation. This could lead to even more innovation and competition. By using AI, manufacturers can stay ahead, enjoying better productivity and efficiency.

The future of AI in industrial automation looks bright. New technologies will likely change how we make things. It’s clear that AI will be key in shaping the industry’s future.

FAQ

What is the role of AI in industrial automation?

AI is changing industrial automation. It makes processes more efficient, accurate, and reliable.

How is machine learning used in industrial automation?

Machine learning helps in optimizing production. It also detects problems and predicts when maintenance is needed. This leads to better products and less downtime.

What are the benefits of integrating AI with IoT in smart factories?

AI and IoT together offer real-time monitoring and predictive maintenance. They also help plan production better. This increases efficiency and productivity.

How does AI enhance industrial robotics?

AI makes industrial robots more flexible and precise. It allows them to adapt to changing needs.

What are the challenges in adopting AI in industrial automation?

Challenges include integrating old systems with new AI. Also, managing data quality is a big issue.

Share this content:

Post Comment